Scope

Between October 2024 and January 2025, Half Bridge Automation regenerated a large fleet of inverters (54 Power Blocks for a total of 12 MW), restoring them to their original performance levels and ensuring the full operability of the plant.

The intervention aimed to reduce production losses to zero, thanks to two strategic choices:

- a hybrid approach to activities (both in the laboratory and on-site),

- on-site work carried out exclusively in the evening hours, to avoid interference with daytime production.

Activity

The inverters showed issues related to efficiency and reliability, with a direct impact on both the quantity and the quality of the energy produced. The activities included:

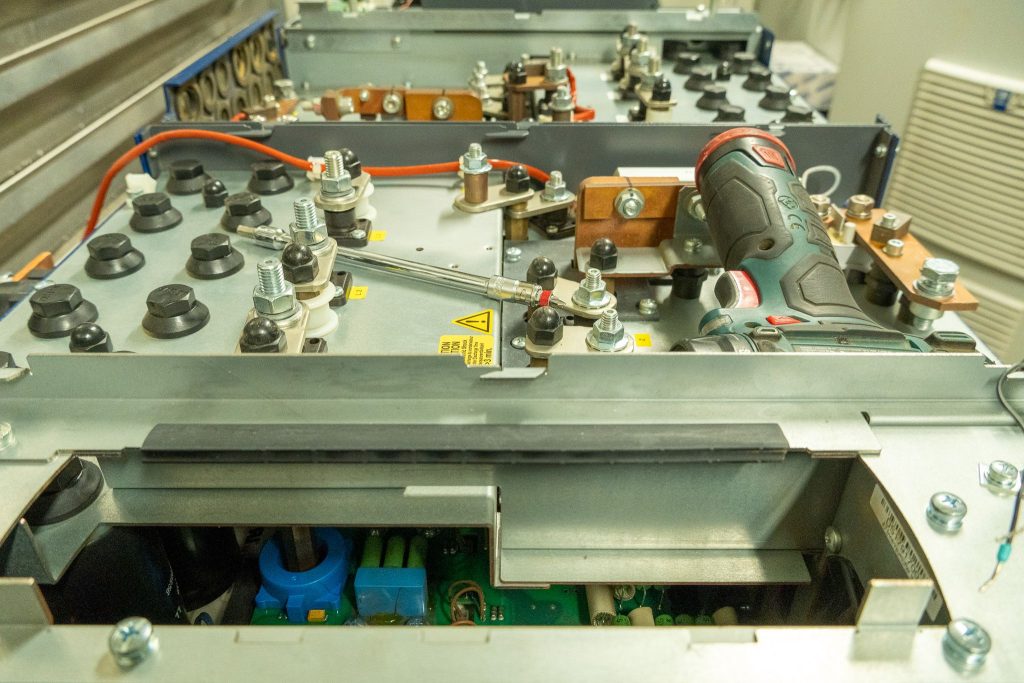

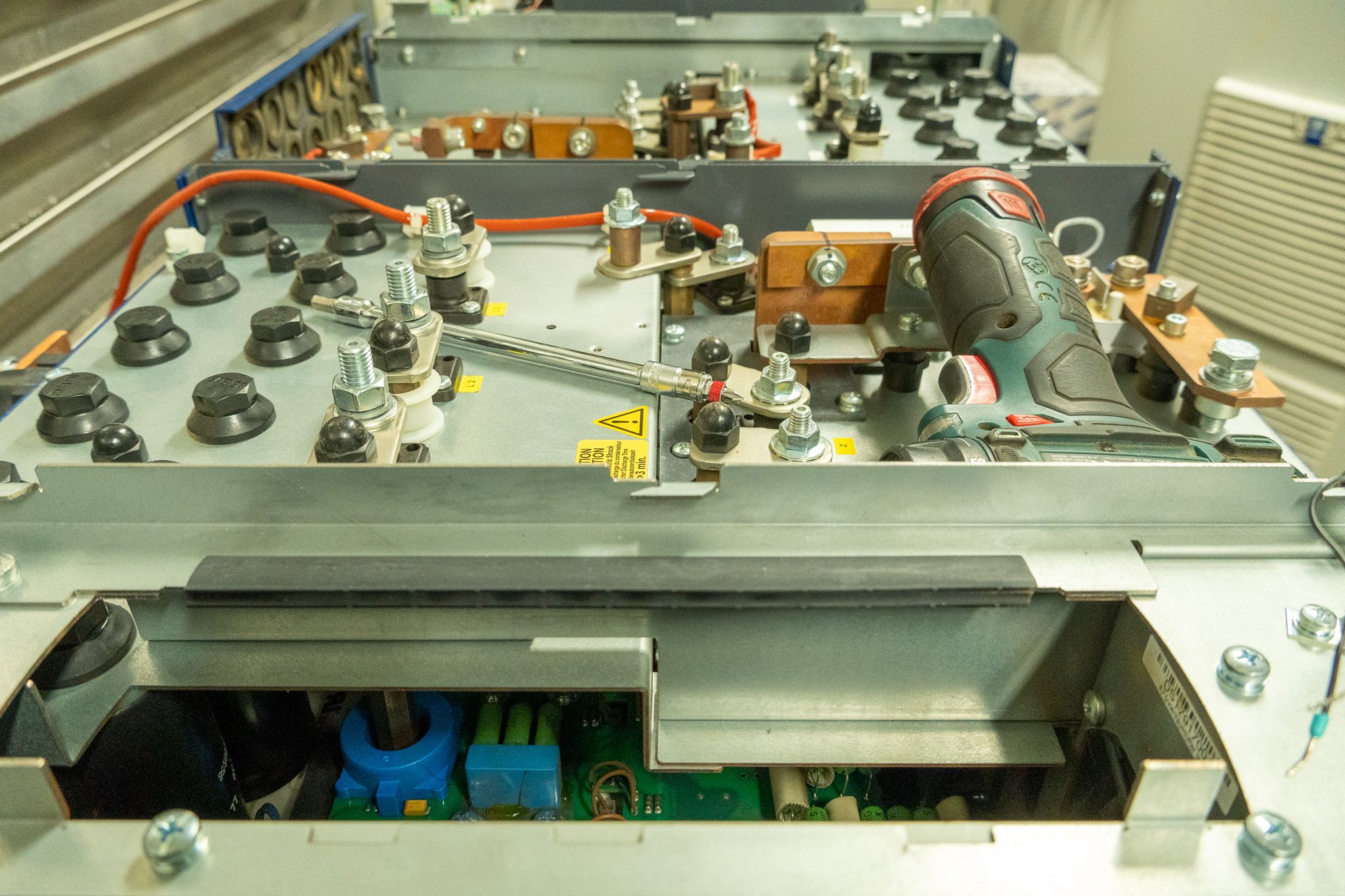

- in-depth diagnostics of malfunctioning units,

- replacement of damaged or obsolete components,

- technological upgrades to increase efficiency,

- stress tests and validation under real operating conditions.

Results

Thanks to this regeneration project, the client was able to rely on greater stability and reliability of the entire system, while also recording a significant increase in production levels. The inverters’ original performance was fully restored, and their lifecycle was considerably extended, bringing a tangible economic advantage in the medium to long term: a substantial saving compared to the costs of a full replacement of the inverters, which would have also implied a gradual drop in production.